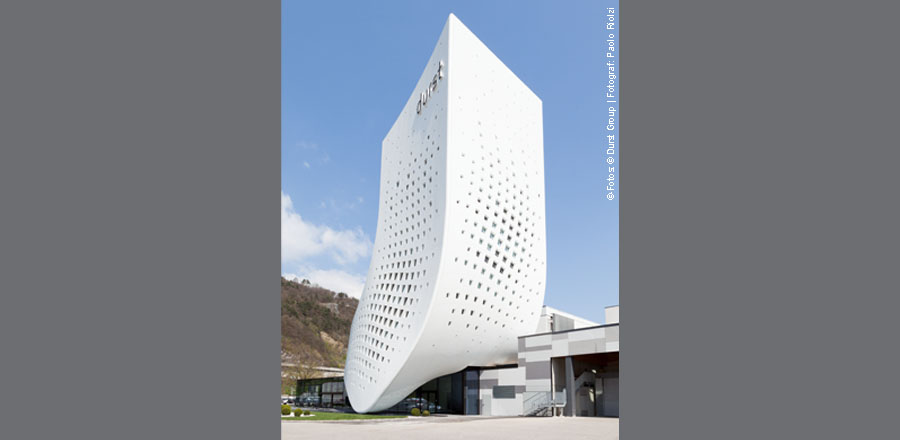

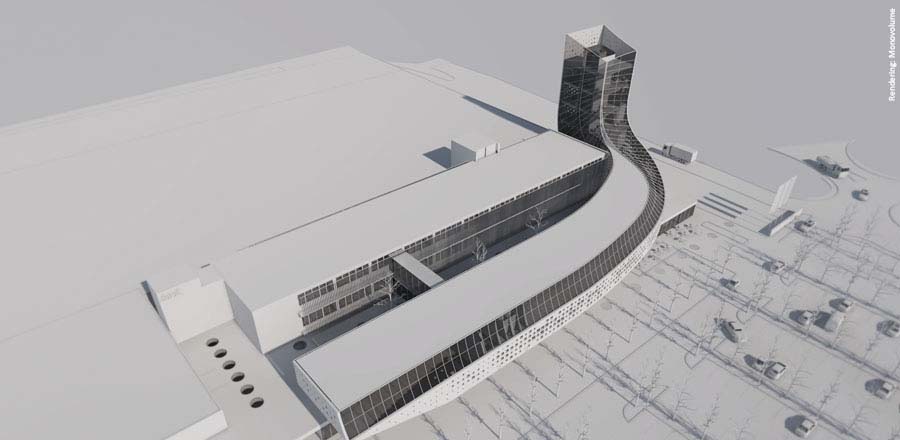

DURST GROUP HEADQUARTERS

Location

Bressanone, ItalyArchitect

monovolume architecture + designData

FRENER & REIFERInstallation Phase:

01.2018 – 03.2019

FRENER & REIFER

Design Phase:

11.2017 – 11.2018

FRENER & REIFER is responsible for the complete design-engineering, fabrication and installation of the external metal facade and roof glazing etc of the new Durst HQ

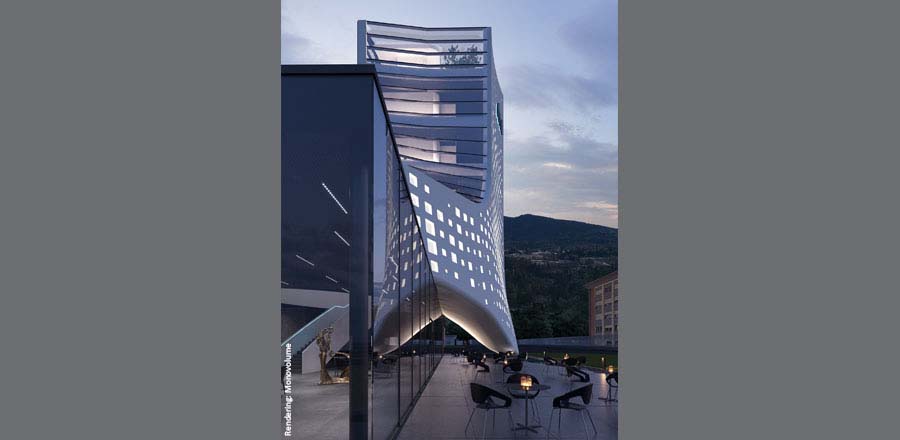

The organically shaped new Durst headquarters building impresses above all thanks to its metal facade with 850 pixel-like, illuminated window elements and 850 m² glass roof consisting of approx. 250 differently sized, partly triangular, insulating glass sheets.

Scope of work

The contract for the facade comprises approx. 7,000 m2

- 2,800 m2 external metal facade in powder-coated aluminium panels with 850 LED lit window elements in various sizes

- 1,800 m2 glulam construction as load-bearing facade element

- 842 m2 roof glazing in approx. 250 different, partly triangular, insulating glass sheets

- 1,100 m2 ground floor transom/mullion facade

- 1,250 m2 faceted transom/mullion courtyard facade curved all-glass facade at 6th floor

- Various sliding doors, a pivot door and an automatic sliding door

- Skylight glazing and a steel/glass connecting bridge

Innovations / Challenges

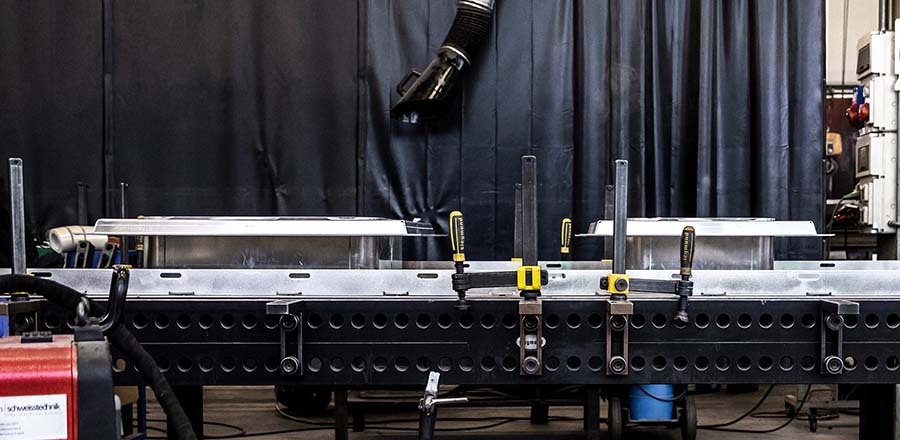

- Extremely tight schedule from design to fabrication to installation

- Freeform metal facade geometry consisting of thousands of different components

- Complex transition from vertical to horizontal roof glazing